The science behind every step of citrus processing

Understanding citrus process science reveals the intricate ballet of chemistry, physics, and engineering that transforms sun-ripened fruit into the juice in your glass.

To achieve the perfect end product, modern citrus process science employs a collection of very small, finite steps, allowing for the greatest control over each variable in the process. Each stage builds upon decades of research into fruit biology, extraction physics, and preservation chemistry.

This journey through citrus process science showcases how precision engineering and deep scientific understanding combine to maximize yield, preserve nutrition, and deliver consistent quality. Here’s the remarkable journey we take and the science behind it.

Here’s the journey we take and the science behind it:

First, the fruit is harvested.

1. Healthy oranges are gathered from the citrus grove.

2. They’re loaded in trucks and hauled away.

3. They arrive at the processing facility, where they are stored in fruit holding bins.

The critical importance of harvest timing in citrus processing

The success of any citrus processing operation begins in the grove. Citrus fruit doesn’t ripen after picking, making harvest timing crucial for optimal juice quality. Fruit maturity is measured by the Brix-to-acid ratio – the balance between sugars and acids that determines flavor profile. For oranges destined for citrus processing, the ideal ratio typically ranges from 12:1 to 18:1, depending on the variety and intended use.

Temperature management during transport is equally critical. Citrus fruit respiration continues after harvest, generating heat that can degrade juice quality if not properly managed. Modern citrus processing facilities receive fruit within 24-48 hours of harvest, minimizing quality loss and ensuring the freshest possible raw material enters the production line.

Fruit storage bins at processing facilities are designed with ventilation systems that maintain optimal temperatures between 45-50°F (7-10°C), slowing respiration while preventing cold damage. This careful pre-processing step preserves the volatile aromatics and flavor compounds that make freshly processed citrus juice so distinctive.

Then, oil extraction begins.

Upon reception of the fruit, there is a fruit washing and grading table to cull fruit.

1. Oil extraction is the first step of the process.

2. Then the liquor is finished.

3. Centrifuging takes place.

4. And citrus essential oil is recovered.

Why oil extraction comes first in citrus processing

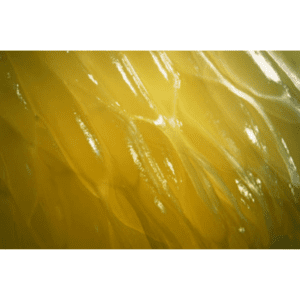

In professional citrus processing, oil extraction always precedes juice extraction, and for good reason. Citrus peel contains 90-95% of the fruit’s essential oils, including limonene, linalool, and other aromatic compounds that command premium prices in flavor, fragrance, and cleaning product industries.

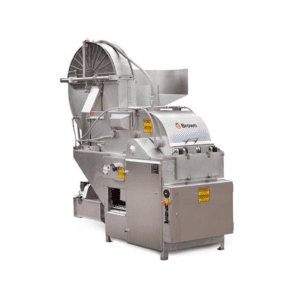

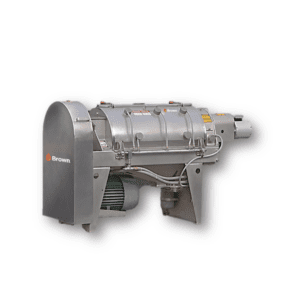

Brown’s citrus oil extraction systems use precisely controlled mechanical abrasion to remove peel oil while leaving the fruit intact, even as citrus conditions change throughout the season. This “cold-pressed” method preserves the delicate aromatic profile that gives citrus oil its characteristic brightness and complexity.

Next, juice extraction takes place.

1. Fruit gets sized to feed proper juice extractor.

2. Fruit settles into the Juice Extractor to squeeze the juice.

3. Juice flows into the Primary Finisher to remove seeds and pomace.

4. Juice with pulp either goes to Secondary Finishing to lower pulp content or is diverted to pulp cell recovery.

5. Pulp cell recovery ensures every pulp cell adds to the mouthfeel.

6. Finally, juice with desired pulp level is concentrated or served as-is, known as NFC.

The engineering behind superior juice extraction

The juice extraction phase represents the heart of any citrus processing operation. This is where decades of Brown’s engineering expertise become evident in every drop produced.

Fruit sizing precision: Before extraction can begin, fruit must be accurately sorted by diameter. Our citrus sizing equipment handles up to 70 tons per hour, using adjustable roller systems to separate fruit into size categories. This precision ensures each piece enters an appropriately sized extraction chamber, maximizing juice yield while minimizing equipment stress.

Engineering services beyond machines

Our comprehensive approach to citrus processing goes beyond equipment supply. Explore our complete citrus processing solutions to discover how Brown can optimize your facility’s performance from concept to commissioning.

Make money out of waste.

Make money out of waste.

Did you know by-products of extraction can be used in animal feed and sold for additional revenue?

One hallmark of efficient citrus processing is the near-complete utilization of every fruit component. What early processors once considered “waste” now represents significant revenue streams that improve the economic viability of the entire operation.

At Brown, we help citrus processing operators identify and implement these revenue-generating opportunities throughout their operations. Our engineering team can integrate by-product recovery systems into new installations or retrofit existing facilities to capture maximum value from every ton of fruit processed.

Engineering services beyond machines

Engineering services beyond machines

Our multi-disciplinary staff can incorporate a variety of custom systems and processes to optimize the outcome of plant installation projects.

Get in touch

Get in touch

Reach out to us to discuss potential partnership opportunities and gather more information.

Our dedicated team of engineers and food scientists is ready to provide detailed answers and insights to any questions you may have.