The science behind every step of citrus processing

To get the perfect end product, it takes a collection of very small, finite steps, allowing for the greatest control over each variable in the process.

Here’s the journey we take and the science behind it:

First, the fruit is harvested.

1. Healthy oranges are gathered from the citrus grove.

2. They’re loaded in trucks and hauled away.

3. They arrive at the processing facility, where they are stored in fruit holding bins.

Then, oil extraction begins.

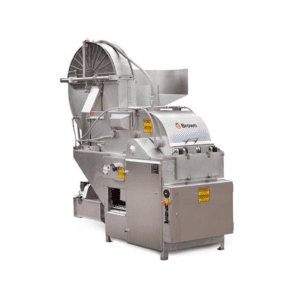

Upon reception of the fruit, there is a fruit washing and grading table to cull fruit.

1. Oil extraction is the first step of the process.

2. Then the liquor is finished.

3. Centrifuging takes place.

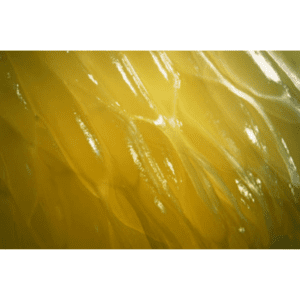

4. And citrus essential oil is recovered.

Next, juice extraction takes place.

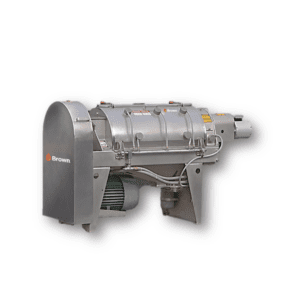

1. Fruit gets sized to feed proper juice extractor.

2. Fruit settles into the Juice Extractor to squeeze the juice.

3. Juice flows into the Primary Finisher to remove seeds and pomace.

4. Juice with pulp either goes to Secondary Finishing to lower pulp content or is diverted to pulp cell recovery.

5. Pulp cell recovery ensures every pulp cell adds to the mouthfeel.

6. Finally, juice with desired pulp level is concentrated or served as-is, known as NFC.

Make money out of waste.

Make money out of waste.

Did you know by-products of extraction can be used in animal feed and sold for additional revenue?

At Brown, we help our clients identify these opportunities along the way.

Engineering services beyond machines

Engineering services beyond machines

Our multi-disciplinary staff can incorporate a variety of custom systems and processes to optimize the outcome of plant installation projects.

Get in touch

Get in touch

Reach out to us to discuss potential partnership opportunities and gather more information.

Our dedicated team of engineers and food scientists is ready to provide detailed answers and insights to any questions you may have.